History

During the mid 1960s, Brooklyn Union Gas Company pioneered the use of an air lance, air compressor, and vacuum truck as a better way to dig and reduce the costs associated with approximately 30,000 annual street openings made for gas distribution pipe repair. Compressed air, or “dry excavation” to dig utility “potholes” proved to be a safe and reliable alternative to manual or mechanical methods of uncovering buried utility lines without damage.

Success with this methodology quickly led to the development of "small hole technology" -- now known as "keyhole technology" -- whereby repairs are made to underground facilities from the roadway surface using long-handled tools. This technology was first reported in the 1960s as utilities sought ways to reduce the size and cost of utility excavations and avoid putting "a man in the hole." Both Philadelphia Electric (PECO) and Peoples Gas of Chicago were early pioneers in developing keyhole maintenance techniques to reduce the number of large street openings that were both a nuisance to the public and costly to excavate and re-pave.

Early keyholing by PECO included repairs to leaking bell joints and cathodic protection. The pavement was cut with diamond saw blades and removed with pneumatic pavement breakers and concrete drills. A power-driven auger and air jet vacuum removed the spoils, augmented by a clam-shell post hole digger. These techniques seem rudimentary compared with today’s rotary coring and vacuum excavators but resulted in substantial savings to PECO.

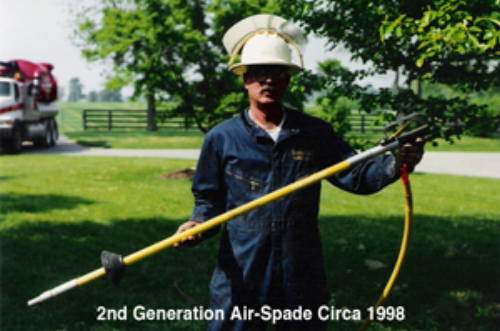

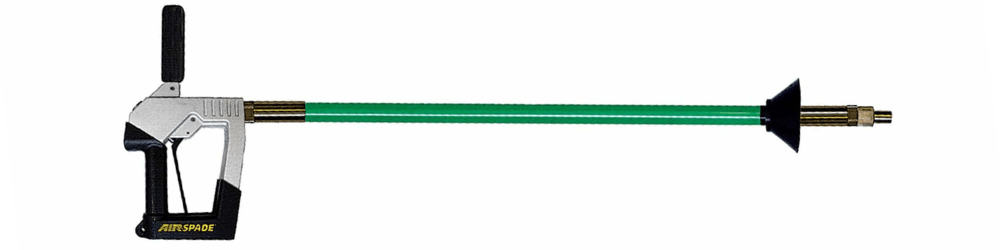

This experimentation led Dravo Corporation of Pittsburgh, PA to develop a specialized air tool for digging, later named "AirSpade", for utility use. In 1985, an independent company, Briggs Technology, Inc. was spun out of Dravo to commercialize this new methodology. In 1991, a group of engineers left Briggs Technology and formed Concept Engineering Group, Inc. (CEG). Along with expansion and refinement of the product line, CEG developed a patented supersonic nozzle, an advancement that greatly increased the effectiveness and efficiency of the tool.

Throughout the 1980s and 1990s, AirSpade became widely accepted by other utilities including Baltimore Gas & Electric, PECO (Excelon), and Pennsylvania-American Water. During the same timeframe CEG also worked with the Department of Defense, applying the AirSpade technology towards uncovering landmines and unexploded ordnance.

Applications within the arboricultural and landscaping fields began to emerge as tree service companies recognized the advantages of this non-impact, non-destructive methodology for tree-care related excavation. As tree-service companies began to recognize the advantages of this diagnostic tool, many new, low-impact arboricultural applications were developed. Bartlett Tree Experts, the largest and most recognized tree service company in the US, was an early adopter.

Today, countless gas distribution companies and their contractors in North America practice keyhole technology using rotary coring, soft excavation, and core reinstatement. This process achieves average savings of almost $1,000 per repair vs. conventional methodologies. In a recent paper, the Gas Technology Institute reported that over 800,000 utility roadway cuts are made per year. Given the inherent safety and cost advantages, the use of soft excavation for trenching, potholing and keyholing is projected to grow significantly over the foreseeable future.

Typical repairs using dry excavation include cast iron main joint repair, sacrificial anode instillation, low-pressure service cut-offs, new service instillation, and valve box replacements. In addition to utility maintenance, these processes have direct application to other underground operations such as test holes, service drops and shallow slice pits for the telecom industry, daylighting and test holes for directional drilling, and inspection holes for pipeline integrity and Subsurface Utility Engineering (SUE).

In 2008, the CEG AirSpade product line was acquired by Guardair Corporation. Since then, sales of AirSpade have grown dramatically through the leverage provided by Guardair’s sales and marketing clout and increased national and international exposure. Currently, AirSpade boasts over 50 active dealers and distributors spread over North America and a dozen foreign countries. With superior performance, user-friendly features, and unequaled customer support, AirSpade has become the industry standard and the tool of choice for thousands of utility and arbor professionals world-wide.